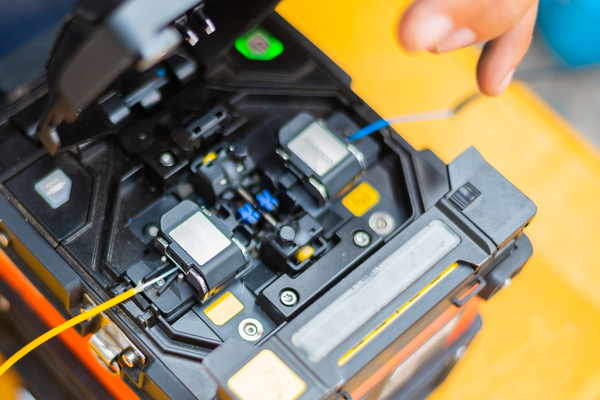

Fiber Optic Fusion Splicing

Call us 24/7

Quick Contact

Download brochure

Fusion splicing is a complex optical fiber joining process that involves skilled fiber optic engineers. It requires joining two optical fibers together using a heat process to ensure that light can pass through seamlessly. If not done correctly, it can result in light scattering or reflection issues.

Achieving a perfect splice is crucial, and it should closely resemble the original fiber optic cable. The heat required for fusion splicing is typically generated using an electric arc, but a gas flame or laser can also be used.

Before the fusion process, precise heat application is essential, and the fiber ends must be carefully prepared by removing all protective covering. Once prepared, the fibers are cleaved to create completely flat ends and meticulously inspected under a microscope to detect any defects.

Fusion splicing is a critical technique in fiber optic technology, and the expertise of skilled engineers ensures a successful and reliable connection between optical fibers.